Introduction

Foam conversion is the process of transforming raw foam materials into functional, finished products that meet real-world needs. Whether it’s turning a simple foam sheet into a high-performance acoustic panel or crafting custom insulation for marine or automotive applications, foam conversion is the bridge between a raw material and a real solution.

In this article, we will explore the world of foam conversion and explain how Acoustafoam uses advanced techniques to create tailored foam products for a wide range of industries.

1. What Is Foam Conversion?

Foam conversion refers to processing foam into a product that serves a specific purpose. This can include simple tasks like cutting foam to size or complex operations like CNC profiling to create a custom acoustic design. Foam conversion turns standard foam into technical foam solutions, making it possible to solve problems that ordinary materials can’t.

From polyurethane foam used in cushions to polystyrene foam for packaging, foam conversion adapts materials into practical products that fit exact requirements.

2. How Acoustafoam Handles Foam Conversion

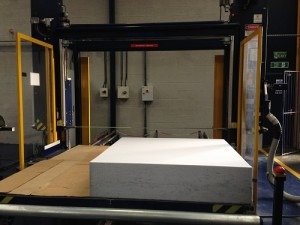

Acoustafoam is a specialist in foam conversion, offering a full range of manufacturing techniques and machinery to deliver high-quality results. Their facility is equipped with:

- Band saw

- Profiled slitter

- CNC profiling machine

- Slitter

- Laminator

- Water jets

- Spray booths

- Die cut press

These tools allow Acoustafoam to transform foam into advanced technical products. With expertise in design and manufacturing, they have supported acoustic solutions in multiple industries.

Real-World Examples

Foam conversion is not just about cutting foam. It’s about solving real challenges such as:

- Sound absorption around radiators in construction vehicles

- Thermal insulation in yacht engine rooms

- Acoustic control in industrial settings

- Noise reduction in marine engine rooms and generator canopies

This is the power of foam conversion: turning a simple foam product into a tailored solution.

3. Foam Types Used in Foam Conversion

Different applications require different foam types. Foam converter works best when the right foam is selected for the task. Here are the most common types:

Polyurethane Foam

Commonly used in cushions, mattresses, insulation, and packaging. It offers flexibility and comfort, making it ideal for seating and acoustic panels.

Polystyrene Foam

Known for being lightweight and insulating, it is widely used for packaging and construction insulation.

Polyethylene Foam

Durable and moisture-resistant, often used in protective packaging and padding.

4. Common Foam Conversion Processes

Foam conversion includes many methods depending on the product requirements. These processes include:

Cutting

Foam can be cut using various methods such as hot wire cutting, water jet cutting, and die cutting. This allows precise shaping and sizing.

Moulding

Foam can be moulded into specific shapes using injection or compression moulding, producing high-precision products.

Laminating

Combining layers of foam or bonding foam to other materials increases durability and performance.

Fabrication

Combining foam with other materials to create finished products like acoustic panels, insulation boards, or protective padding.

5. Why Foam Conversion Matters Across Industries

Foam conversion plays a key role in many sectors due to its ability to create custom products quickly and efficiently. Here are some common applications:

Packaging

Custom foam packaging protects delicate items during shipping and transportation.

Seating & Cushions

Foam conversion is essential for producing comfortable seating in furniture and automotive interiors.

Insulation

Foam is widely used for thermal and sound insulation in buildings, vehicles, and machinery.

Medical Products

Foam conversion produces orthopedic supports, medical cushions, and protective padding.

Automotive Components

Headrests, armrests, and interior insulation are all products of foam conversion.

6. Customization and Quality Control

A key benefit of foam conversion is customization. Foam conversion allows designers to create products with specific shapes, thickness, and performance characteristics.

At Acoustafoam, quality control is a priority. Every product goes through strict quality checks to ensure it meets industry standards and customer requirements.

7. Class 0 Foam: Fire-Safe and Acoustic-Friendly

One of Acoustafoam’s most important products is Impregnated Class 0 Foam, a foam treated with a mineral compound to provide nil burn rate for high fire-risk applications.

Key Benefits of Class 0 Foam

- Fire-resistant

- Non-dusting and chemically inert

- Flexible and easy to shape

- Excellent sound absorption

- Ideal for engine rooms, generator canopies, heavy vehicles

Class 0 foam can be supplied in sheets, rolls, facing, or profiled form. It is also available with additional coatings or composite layers such as lead foil, polymeric barriers, and damping sheets.

High-Density Class 0 Profile

High-density Class 0 foam offers exceptional acoustic performance and is non-fibrous, meaning it does not erode or migrate in airflow. It is safe and easy to handle, making it suitable for applications like cabin trim panels or headliners in the automotive sector.

8. Acoustic Foam: The Key to Better Sound

Acoustic foam is a popular solution for improving room acoustics and controlling sound reflections. It is commonly made from polyurethane or melamine foam and comes in shapes like wedges, pyramids, and egg crates to increase surface area and sound absorption.

How Acoustic Foam Works

- Absorbs sound waves

- Reduces echoes and reverberations

- Improves speech clarity and audio quality

Where Acoustic Foam Is Used

- Recording studios

- Home theaters

- Offices

- Public spaces like restaurants and auditoriums

Installation Tips

- Cover at least 20-30% of wall surface for noticeable results

- Place foam at reflection points and corners

- Use spray adhesive or mounting brackets for strong adhesion

Limitations

Acoustic foam improves sound within a room but does not fully block sound from entering or leaving. For full soundproofing, it must be combined with materials like mass-loaded vinyl, drywall, or resilient channels.

9. The Benefits of Foam Conversion

Foam conversion offers several advantages that make it a preferred choice across industries:

Benefits

- Custom shapes and sizes for precise requirements

- Improved acoustic and thermal performance

- Durable and long-lasting products

- Flexible and easy to handle

- Eco-friendly options available

- Ideal for technical and complex applications

Conclusion

Foam conversion is a powerful manufacturing process that turns raw foam into high-performance products for diverse industries. From acoustic panels to fire-safe insulation, foam conversion allows custom solutions that meet specific design and functional needs.

With advanced machinery and industry expertise, Acoustafoam is capable of producing high-quality foam products, including Class 0 foam and custom acoustic solutions, tailored to each client’s unique requirements.

If you need professional foam conversion services, don’t hesitate to contact Acoustafoam using their contact form for expert guidance and product support.